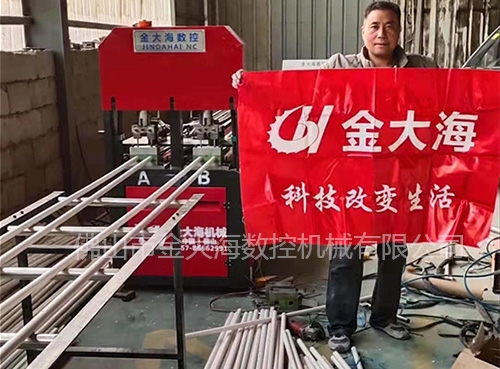

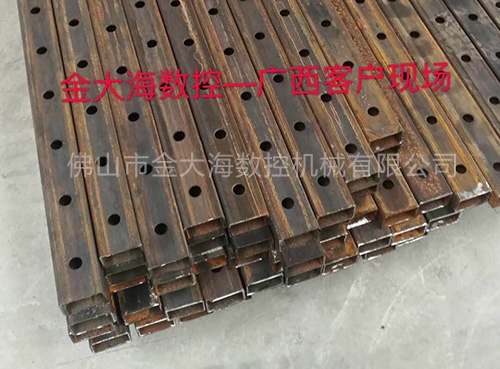

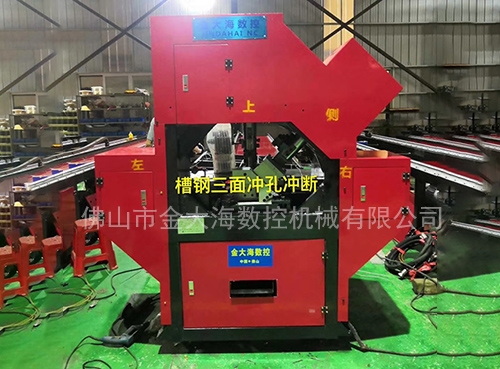

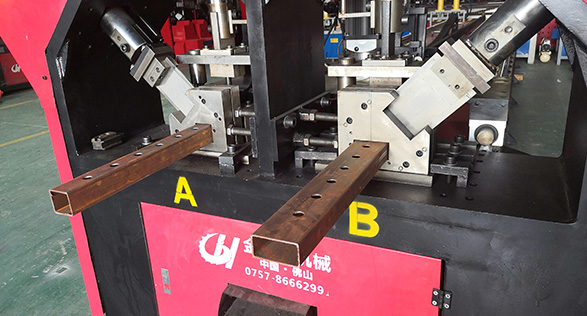

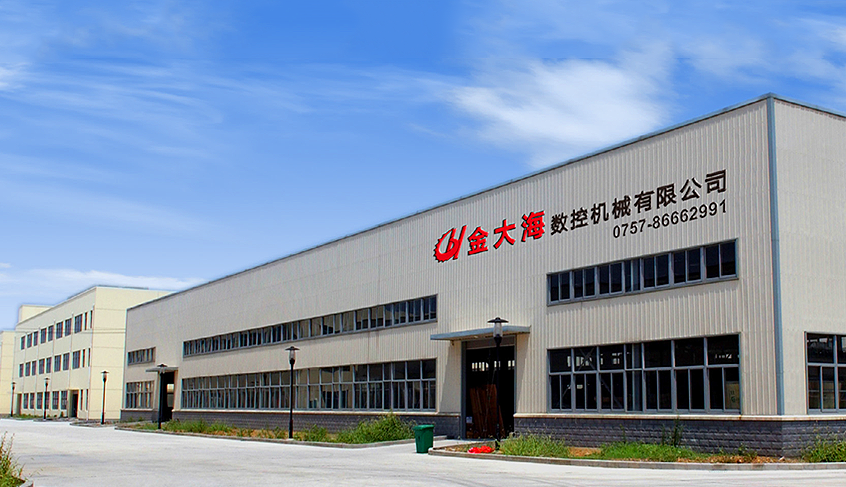

Foshan Jinhai CNC Machinery Co., Ltd., which had been producing, researching, developing and manufacturing precision hardware molds from 2007 to 2013 in the early stage, was founded in 2014 and renamed Jinhai CNC after the combination of three certificates in 2018. It is located in the second industrial zone of Baishaqiao, Shishan Town, Foshan, about two kilometers away from the Foshan Shanxi Station. It is a professional R&D and production automation equipment. The main products include CNC punching machine for building climbing frame and ladder, CNC punching machine for angle steel channel, CNC punching machine for stainless steel anti-theft net, punching machine for zinc steel guardrail fence, and other customized CNC equipment for pipes and profiles. The company has gathered a group of senior R&D technicians with rich welding experience, mold design and automation design, and has a management team specialized in mechanical assembly, automation control and electromechanical integration.